Smoke-free

Cook Stove (mud)

This project was inspired by a

situation observed in Guatemala. While visiting the refugee village

of El Gorrion, I found myself gagging on smoke drifting from a nearby

kitchen door.

A woman was cooking on a masonry bench

over an open fire with no chimney, but there was an opening in the

roof where smoke could exit – prevailing winds permitting. I had

seen such cooking arrangements in various parts of Mexico as well.

Next to this was a larger stove with an

expanse of steel plate and a vented chimney. This was not being used

because it required too much firewood. I had earlier spotted a

propane stove in another room that was likewise not being used. In

that case, they could not afford the propane. Here we have two

solutions to a very serious and widespread health hazard that are not

being employed because of economics.

Upon returning to the States

I began to define what it would take to solve this problem:

It must be smoke free, or nearly

so.

It must require the same or a

lesser amount of firewood.

It must use materials that are

cheap and locally available.

It cannot be larger than the

existing cooking area.

It must require little or no

modification of existing cultural practices.

It must be perceived as desirable

to the target population.

Tooling requirements must be

cheap, and accessible in the target area.

I built a 21” square box from scraps

of plywood on hand, and packed it with earth. This mass was then

sculpted internally to create a burn chamber, channels for combustion

air and exhaust flow, and a dual-function cooking surface. The

resulting prototype serves the above criteria in a variety of ways:

Typically, slightly more than 40%

of the energy in firewood is in the form of smoke. By burning the

smoke, less firewood is needed.

The fire is completely contained

within the structure, so less energy is lost to convection.

The flue gasses are contained and

directed against the bottom of a cooking vessel, rather than being

free to wander around it and be wasted.

This exhaust then flows across the

bottom of a steel plate, so that tortillas etc may be prepared while

food is being boiled. Doing both of these at once instead of in

sequence per tradition, shortens the amount of time that the fire is

needed.

The fire itself is well served by

small twigs and other scraps not normally useful as firewood. This

greatly increases the amount of locally available fuel.

In addition to these five

techniques for reducing expense, an externally vented flue

eliminates what may remain of the smoke.

The prototype was sculpted from

earth – available anywhere but downtown. About 10’ of 4”

single-wall flue pipe is required, and also a small plate of steel.

The area of the top surface of

this prototype is smaller than any cook surface I’ve seen in the

homes I’ve visited, but scaling upwards by a few inches should be

no problem.

This stove could be sculpted from

an existing cooking bench. This would insure economy, size, and

minimal impact upon cooking practices.

There is no way to predict the

acceptability of this stove with any certainty. It may need to be

demonstrated or otherwise marketed before cultural acceptability can

be ascertained.

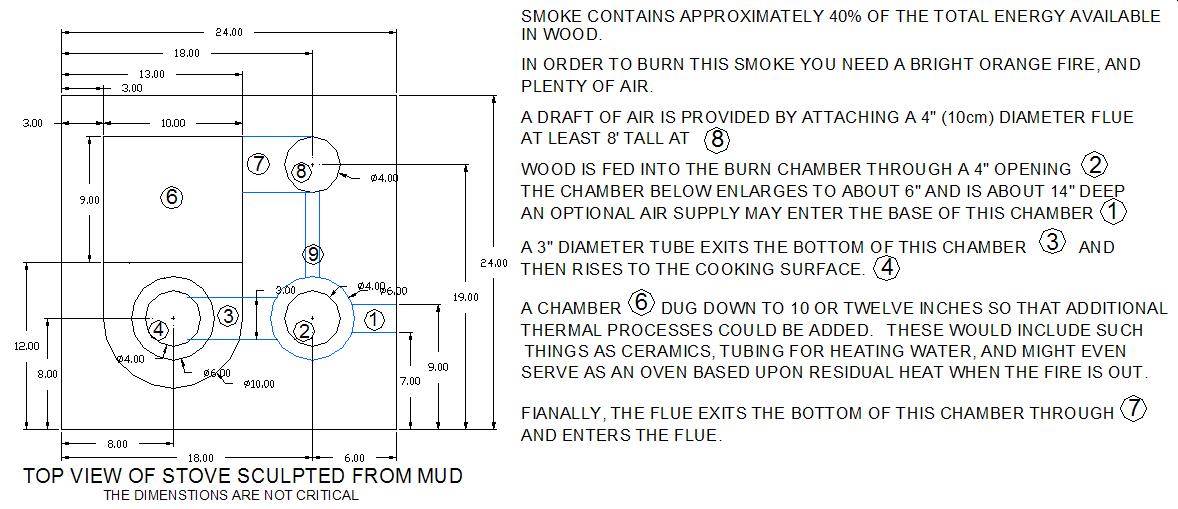

In this top view, the 4” hole

on the lower left opens out to a 6” diameter burn chamber a few

inches below the surface. The overall depth from the top surface is

about 14”

The exhaust from this burn is taken

from the bottom of the burn chamber and directed upward through the

4” hole rising in the pit in the upper part of the photo (You can

see the terracotta coloring lining this hole resulting from the

firing of the earth by the high-temperature exhaust).

When the plate in the upper left is

placed over the pit, a pot covering the hole receives the full

benefit of this blast. The flue gasses then pass under the plate and

exit into the flue which is inserted in the 4” hole at the lower

right.

For the benefit of any interested, I am

including drawings showing the approximate dimensions of this unit. I

also add a few additional notes and comments.

Adjustments:

The photos above are of my very first

attempt at this type of stove. Although it seems to work very well,

there is currently no base of application experience (other than a

test that showed it could boil water faster than our modern gas stove

in the kitchen).

Materials

This original was made from earth far

more suited to gardens than structures. I would recommend trying a

mixture of coarse sand, clay, and maybe some dried grass mixed in –

here’s my reasoning:

Without some clay, the soil will

crumble too easily, even when completely dry.

If it is pure clay, the thermal

stresses and drying will create cracks, and possibly explode pieces

off from the insides of the chambers and passages.

The grains of sand will not expand

and shrink with temperature changes as much as the clay, and changes

in moisture will not affect them at all. This will help stabilize

the mixture.

Cracks attempting to propagate

through the mass will be frustrated by constant detours around the

grains of sand.

I am uncertain as to the optimum

ratio of sand to clay, but feel it should be just enough to glue all

the grains of sand together. I don’t think the ratio is very

critical, but I would expect that about three parts sand to one part

clay would be an acceptable starting point – almost anything would

be better than the garden soil I used.

The dried grass would permeate the

mass with small tubes as it decayed, and was burnt out. This would

increase the insulating properties, relieve thermal stresses, and

terminate cracks. This could be very important when higher ratios of

clay are used.

Perhaps a higher percentage of

clay with a small amount of cement added would be a good as a

plaster for hardening the top surface.

Tooling

In seeking to verify the simplicity of

this project, I filed a chisel edge on a 2-foot length of 1/8” X ¾”

mild steel to use as a sculpting tool. It was quite effective. I also

used a simple screwdriver to define internal passages. The entire

project could be well served by these simple tools.

Skill and patience could have created

the nice round holes you see in the photos above, but having neither,

I designed and fabricated the 4” diameter auger that actually

produced them. It may sometimes be desirable to sculpt such a stove

from an existing cooking platform. I was able to drill my auger

through a well-dried experimental block of one-part clay to two parts

sand, and use the chisel mentioned above to sculpt a well defined

notch in it. This approach appears to be quite practical. In cases

where an existing cooking platform is brick or concrete, a hammer and

a tool-steel chisel may be required.

Although the auger was only about

two-feet long, the shaft was made of ½’ all-thread, topped by a

handle that could be unscrewed. This enabled me to add extensions if

I ever needed a deeper hole. A stove-related application of this

could involve boring down through a common 3’- thick adobe wall.

Care must be taken however to adequately cap such a chimney so that

water could not enter and deteriorate the wall.

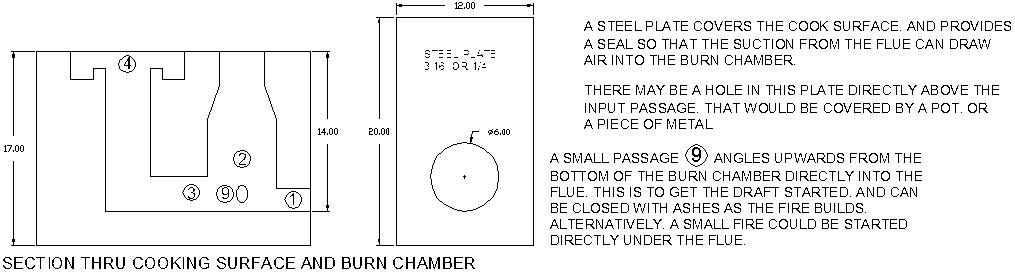

Principles

In order to burn the smoke (and render

the additional 40% of the available energy I mentioned), you need a

bright orange fire, and plenty of air. Therefore a stack of at least

eight or ten feet is essential to create a strong enough draft.

This must also be coupled with a good

seal between the burn chamber and the flue. Air leaking under the

edges of the steel plate, and from around the pot or plate sitting

over the hole in the plate can significantly reduce the stove’s

effectiveness.

During the burn it would be well to

cover either the hole above the burn chamber, or the vent that comes

in from the side (the top could be covered by a second cooking vessel

for that matter).

In the photos and drawings you can see

that the pit is shallower on the end where the flue gasses enter.

This is to force them closer to the bottom of the pot. By creating a

raised ring around this opening (visible in the drawings but not in

the photos), the pressure against the gasses can be relieved

immediately after their application to the bottom of the pot. This

allows for a better draft.

The intent of the pit is to allow for

further options and experiments – consider:

I have already been able to fire a

simple clay structure in a second prototype with a larger pit. Any

household using such a stove could also dabble in ceramics.

If the deep end of the pit were

14” X 10” X 7”, you might be able to fire a brick 12’X6”X4”

(30cm X 15cm X 10cm) every time you cooked. By the end of a year

just one brick per day would give you a wall a meter high by at

least three meters long. A community project could doubtless be

served within weeks.

Bricks of this size could span the

pit, creating thermal storage and insulation that would allow the

pit to serve as an oven after the fire was out. Indians of the

Southwestern United States would cook their bread by building a fire

in a clay oven, then removing the ashes, and inserting the dough.

A fire could be built in the pit

itself to roast meat in a vented barbeque.

Piping could be installed to heat

water in a tank elevated adjacent to the stove – a primitive

kitchen with hot running water!

A Stirling-cycle engine could be

run off this scavenged heat to produce enough electricity for modest

lighting – enough! I’d better stop before I get too far out of

hand, but I still have a lot more ideas.

I am certain that needs and local

inspiration in the field could contribute much to this project, and I

would be quite eager to hear of anything related to this that may

occur in any part of the world. I am also quite interested in

discussing appropriate technology needs that may arise from any

quarter.

In closing

It is ironic that while in the United

States we are seeking to wean ourselves of a petrochemical addiction,

the poor in developing nations might leapfrog past us to a high

quality of life, while maintaining a locally sustainable

infrastructure.

This cannot happen unless attention is

given to growing fuel locally. This stove can effectively use twigs

unsuitable for current cooking fires, and it can thereby decrease the

wait between planting and harvesting of fuel. It is essential

however, to fill in fence rows and any unused spaces with fuel

plants.