Refrigeration

If

you were to double the pressure within a container of air, its

absolute temperature would double.

Since

absolute zero is about -460 degrees F, air starting at 70 degrees

would begin at 70+ 460 = 530 degrees above absolute zero. So, by

doubling the pressure on two cubic feet of 70 degree air (increasing

it to only about 30 PSI), we raise its temperature to 600 degrees F

(530 X 2 - 460 = 600).

Generally

we aren't aware of all this heat, because air stores very little of

it, and so it dissipates almost instantly. However, if you have been

around air compressors, you know they get hot, and now you know why.

When

air expands, it cools according to the same ratios. If you have had

much experience with air-powered tools, you know that frost can form

as the air expands through them. Under these conditions, air is first

compressed, its increase in heat is allowed to escape, and now as it

expands it cools to a lower temperature than that at which it was

stored.

So

why isn't this principle commonly used in refrigeration today? Ask

the refrigeration industry. Theory says it must work, and the frost

on my air-powered grinder says it does work. Furthermore, this

process is often used commercially to achieve cryogenic temperatures.

Consider

the drawing below for a practical air-based refrigerator system:

1. Ambient

air is compressed on the left.

2. The

resulting heat is dumped through the radiator.

3. The

air that has been cooled by the radiator is allowed to expand through

an air-powered motor on the right.

4. This

expansion reduces the temperature further – to below the

temperature of the input air.

The

mechanical energy from the air motor is returned to assist the drive

motor in powering the compressor. There would be less energy

returned of course, because the volume of the cooler air at the

right end of the radiator would be less than that of the hot air

entering the left end of the radiator (although obviously they would

be at the same pressure).

For

mechanical simplicity, the entire system (except the radiator) could

be combined on a single shaft as shown below:

Take another look at this

illustration:

Take another look at this

illustration:

· By

applying pressure to the “to” side of the radiator port, it

becomes an air or steam-driven motor, turning counter-clockwise.

· By

switching the pressure to “from” port, you could drive it

clockwise, albeit at a slightly reduced efficiency.

· By

placing the “in” and “out” ports outside a space to be

heated, and the radiator on the inside, and applying power to rotate

it clockwise, the unit becomes a heat pump.

Radiation

Refrigerator

This

idea is based upon the fact that on a clear night, about 20 to 40 BTU

per hour can be radiated into deep space for every square foot of

flat-black surface.

The

design goal (untried) here is to keep two gallons of water or milk

below 45 degrees on a 100 degree day, in a box 12"x 18" x

12" deep.

If

we allowed 2 gallons of water (or milk) to rise in temperature from

32 degrees F to 45 degrees F, this would mean we were losing 217 BTU

(2 X 8.345lbs X 13 degrees).

With

8 square feet of surface area on the box, we would be obtaining

27.125

BTU per square foot (217/8=27.125).

If

we defined the non-cooling portion of the day as 16 hours, we would

be warming the stored fluid by 27.125/16 = about 1.7 BTU per square

foot per hour.

If

we had an average daytime outside temperature of 100 degrees, the

temperature difference would be 100-32 = 68 degrees. If we divide

this by 1.7 BTU per hour, our insulation would need an "R"

value of 68 / 1.7 = R40.

Counting

on at least 2 hours of 20 BTU per square foot per hour radiation per

night, the radiator surface area we would need to dump 217 BTU during

this time would be: 217 BTU/2 hours/20 BTU per hour = 5.4 square

feet.

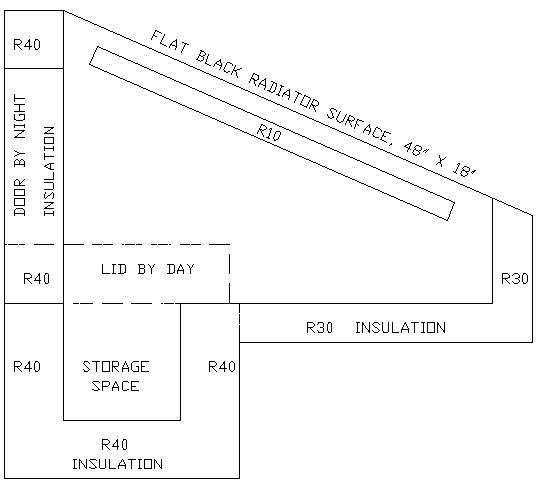

Now

this is a lot larger than the top our 12" x 18" cold

storage box, so a cross-section of the radiation refrigerator that I

haven't built yet, would look something like this:

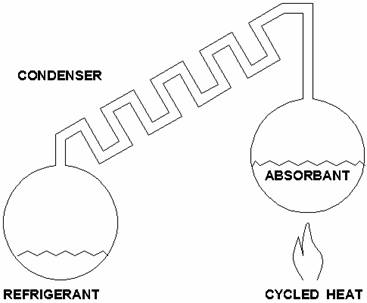

Sounds

like an oxymoron – but wait! Some of you are familiar with

propane-powered refrigerators common in motor homes and camp

trailers. Does it make any sense to get cooling out of a flame?

There’s a trick to it; it’s called absorption cooling.

A

refrigerant is absorbed into a liquid or solid at normal

temperatures, but driven out when the temperature is raised beyond a

certain point. This vapor then passes through a tube to a cooler

place where it is condensed and stored in another container in liquid

form.

When

the heat is off, the material in the original chamber begins to

reabsorb refrigerant vapor in the system and a vacuum is created.

This

causes the refrigerant to draw heat from (cool) its environment as it

evaporates, while being reabsorbed in the original chamber.

As

a residential solar cooler, consider an absorbent system heated by

concentrating the morning sun on the east side of the house. This

drives the refrigerant through the condenser where the heat is

exhausted out of the dwelling, and into the other container in liquid

form.

By

the afternoon, the sun has moved on and the reabsorbing process

begins, cooling the dwelling. It might well be practical to use the

condenser to also provide the cooling surface, by re-routing the air

downward into the dwelling. Conceivably the entire process could be

passive if the condenser were above the dwelling. This is because the

heat and cold would naturally flow upward and downward, respectively.

Stirling

In

the “Engine” category you will find a remarkable device called a

“Stirling Engine”. As an engine it produces mechanical energy if

you have sources of hot and cold, but it has another trick. If you

mechanically rotate it, it will actually produce a temperature

difference. In fact, specially-built Stirling engines are used to

achieve cryogenic (super cold) temperatures.

Take another look at this

illustration:

Take another look at this

illustration: