16’

Bolt-Together Dome

R.

Buckminster Fuller was a visionary born near the end of the

nineteenth century. As a man concerned about the world’s

shortages, he invented the geodesic dome as a means of enclosing

large volumes with a minimum of material.

I

first built this dome in the early seventies for about $50. Since

then this structure has served as:

*

Shade

*

Hammock support

*

Tent in various campgrounds

*

Child’s swing support

*

Bedroom

*

Greenhouse

*

Storage

*

Shop

*

Swap-meet shelter

*

Garage

*

Cement form

*

$200 instant cash when a passing stranger wanted it bad enough.

This

list is by no means complete, but it's a good start.

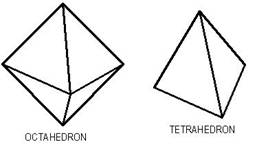

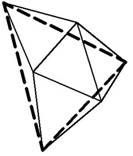

A

solid object with all its surfaces the same shape and size is called

a regular polyhedron. A few examples of regular polyhedrons are shown

here:

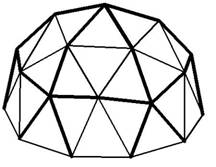

A

geodesic dome is usually created by adding additional faces to a

polyhedron. Since the icosahedron comes the closest to being a

sphere, it is the one most often used for this purpose.

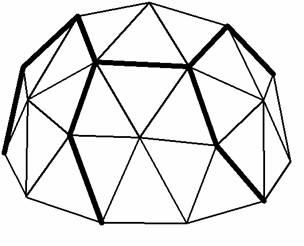

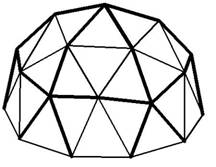

Picture

a sphere just big enough to surround a polyhedron. Now stretch

the center-point of each line so it touches the sphere, and connect

these points with additional straight lines. It is important to note

that length of these additional lines will be longer than the others

(The darker lines in the dome illustration below represent the

shorter lengths). Also notice, that their ends connect six lines,

instead of the five-point connections of the original icosahedron.

We

have just created the simplest form of geodesic dome. If we wanted to

get more complicated, we could now take the centers of each of these

lines and project them to the sphere, and so on. For our dome,

however, we’ll keep it simple.

The

frame for this 16'8” diameter dome can be built for about $120

(as of March 2010). Properly covered it can be weather-proof and easy

to heat. The cost of the coverings varies widely, but is typically

less than the cost of the frame. It breaks down to a bundle of struts

a little over 5 feet long with a weight of less than 150 lbs.

On the

interior left, you can see the partition curtain that separates the

master bedroom and bathroom from the living-dining area.

Various

sections of the covering could be temporarily removed or installed to

optimize the momentary preferences of sun, shade, and ventilation.

The

entire camp loaded nicely into the 6'-long bed of a compact pickup,

and you could still see over the load through the rear-view mirror.

When we

would rent a campsite for a week at a time the appointments of this

cabin included a self-contained flush toilet, and a bath pan we would

use for hot solar-heated baths every afternoon. This of course

included the usual kitchen, wood stove space heating, lighting,

chairs and hammocks as desired.

From

this cabin-campsite base we would tour an area with all the

convenience of a nearby home (using the economy vehicle that carried

it).

The

dome frame is made from 3/4" thin-wall conduit. It's 16' 8-1/2"

in diameter, about 215 sq.ft. in area, and weighs about 130 lbs.

Disassembled, it packs into a bundle of struts about 11" in

diameter by a little over 5' long.

Twenty-six

1/4" X 1-1/2" bolts plus nuts are needed to bolt it

together.

It

requires two different strut lengths so I calculated where to cut a

10' piece of conduit so you would get a long one and a short one out

of each stick (that is how it came out to 16' 8-1/2" diameter).

You need five more long ones than short ones, so for the 65 struts

required, you'll need to buy 35 10' sticks.

Cut

each one 63-9/16" from one end, and flatten about 2" on

each end of the two resulting pieces. I have found that about a

3-pound hammer and a stump or “biscuit” of wood makes an

ideal pounder and anvil for this application.

MAKE

SURE that the flattened ends are in line with each other, rather than

twisted into different planes.

DO

NOT use a driveway, concrete floor, or concrete anything else as an

anvil. The repeated shock of even this hammer will begin to produce

cracks far sooner than you might imagine. If you do happen to have a

steel anvil available, make sure it’s in the middle of a wooden

table, or otherwise isolated from any concrete slab.

Use

a center-punch to mark a drill position in the center of each

flattened area, about ½ inch in from each end. I have found

that if you use a wooden backing, and drive the punch hard (almost

through the metal) it takes a whole lot less time to drill the holes.

Drill

a 5/32” hole in each end of each piece.

Bend

the ends about 15 degrees in the same direction, so they will be

tangent to the same 16’ sphere.

Coverings

for this dome have included various forms of plastic, a parachute,

wood, and even cement. One I’ve found surprisingly satisfactory

is 6-mil black plastic lightly sprayed on both sides with aluminum

paint. The aluminizing radically reduces the heating of the sun on

summer days, and helps trap the radiant heat of a camp stove and

bodies on a cool mountain morning.

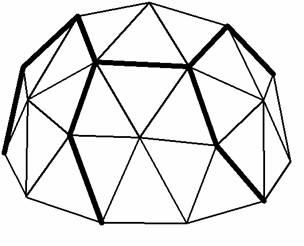

The

method I find most versatile is to divide a covering of plastic or

tarp into six pieces – one for the top, and five around the

sides. The boundaries of these pieces are outlined by the heavier

lines on the sketch below.

The

method I find most versatile is to divide a covering of plastic or

tarp into six pieces – one for the top, and five around the

sides. The boundaries of these pieces are outlined by the heavier

lines on the sketch below. The

covering pieces are attached by pulling their edges around the struts

indicated by the heavy lines above, and hooking them on #10 x 3/4”

sheet metal screws spaced 8” apart. Seven screws per strut,

with the middle one centered, work out nicely for these lengths. The

screws should be installed in the same plane as the flattened ends.

Five

long struts will need these screws to secure the top cover, and ten

short struts with screws will be required to run down the sides.

The

edges of temporary coverings of plastic sheeting may be simply

impaled on the heads of the screws. More substantial materials can be

fitted with grommets.

When

forming a two-dimensional sheet to a three dimensional surface,

you’ll need to take up some slack around the edges. Fold the

excess along one of the struts and secure on both sides with duct

tape (unless you feel like sewing).

By

overlapping the edges of the coverings as shown below, you can get a

pretty good measure of protection from the elements.

In

taking another look at the illustration below, notice that five short

struts (indicated by the heavier lines) will join at the original

points of the icosahedron. The other ends of these struts are joined

by four long struts and one other short strut.

may

be a hundred different sequences for bolting this thing together, but

here are couple suggestions to get you started.

Besides

the struts – some with sheet metal screws preferably –

nuts & bolts, it’s nice to have a few tools. Although a

pair of 7/16 end wrenches can do this, a ratchet fitted with a 7/16”

deep socket is a great help. If you bought carriage bolts instead of

hex-head (as I prefer), you’ll need a pair of vice-grips to

grasp the heads. Vice-grips are handy anyway, to help adjust errant

strut ends, and to compress stacks of them while bolting. You should

also have a hammer, something to stand on, and a friend.

1.

Lay out a circle of ten long struts on the ground. This will

establish the size and position of the finished structure, and leave

you with only fifty-five more struts to worry about.

2.

Build the dome up to the zigzagging ring of ten short struts (heavy

lines) about four feet off the ground.

3.

Connect additional struts to join a ring of five long struts near the

top.

4.

Join the remaining five struts with a single bolt into a spoke

pattern, and handle this as a group.

5.

Once everything is together, walk around the frame a couple of times

adjusting the position of each of the ten connections on the ground

to relieve stresses and conform to any irregularities.

6.

Tighten everything down, and go around lightly tapping in all the

sharp edges with your hammer, so you won’t tear your covering.

I also like to add a piece of duct tape over each of the bolts to

further reduce wear on the covering.

As

you build it, aim the screws in the five long struts around the top,

inward, and the screws on the short struts all towards the right.

This will give you consistency and a water-shedding overlap when it

comes to applying the covering.

This

structure has quite a bit of volume for its weight, so under windy

conditions so you might prefer to tie it down to terrorizing the

neighborhood with an exceptionally large tumbleweed.

One

very secure way of doing this is to flatten and drill one end of

short (about a foot) pieces of tubing. Dig small holes under the

connections on the ground, bolt on the short pieces, and cast them in

concrete.

In

one case, I dug a ditch about 6” deep around the perimeter and

laid the bottom of the plastic in it. When this “skirt”

was covered with dirt, it made a secure, draft-free seal.

The

method I find most versatile is to divide a covering of plastic or

tarp into six pieces – one for the top, and five around the

sides. The boundaries of these pieces are outlined by the heavier

lines on the sketch below.

The

method I find most versatile is to divide a covering of plastic or

tarp into six pieces – one for the top, and five around the

sides. The boundaries of these pieces are outlined by the heavier

lines on the sketch below.